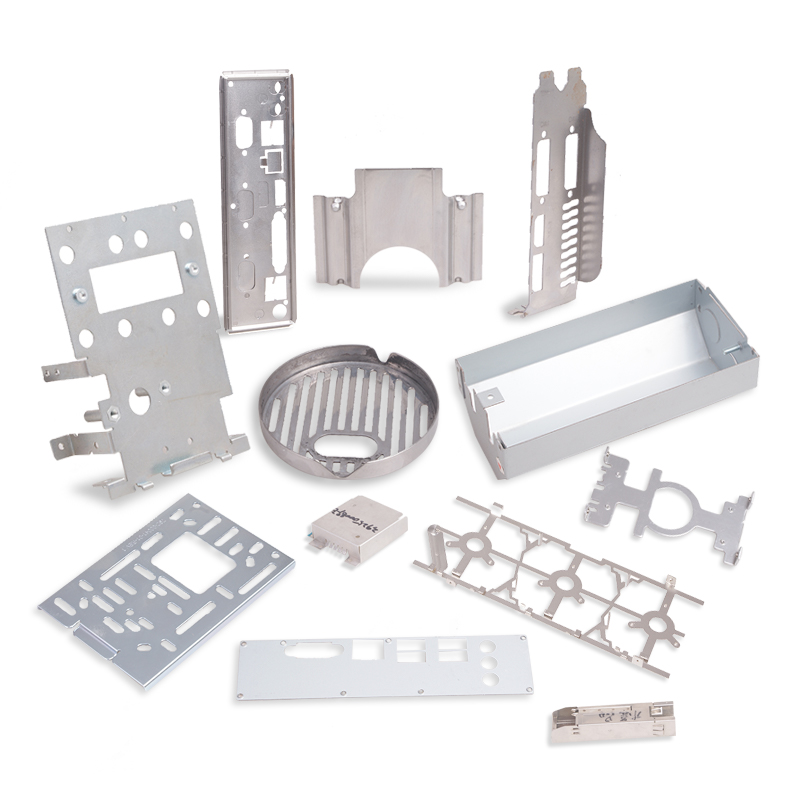

New Products

Find Sheet Metal Fabrication Stamping, Sheet Metal Welding Product, Sheet Metal Product Parts on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Unit Price: | 6 USD |

|---|---|

| Min. Order: | 10 Piece/Pieces |

The processing steps of parts processed in the sheet metal workshop are: preliminary product test, product processing trial production and batch production. In the process of product processing and trial production, timely communicate with customers and obtain the evaluation of corresponding processing before mass production.

Laser drilling technology is the earliest practical laser technology in laser material processing technology. In the sheet metal workshop, pulse laser is generally used for laser drilling, which has high energy density and short time, and can be processed for 1 μ M is especially suitable for processing small holes with a certain angle and thin materials. It is also suitable for processing deep small holes and micro holes on parts with high strength and hardness or brittle and soft materials.

Laser can realize the drilling processing of burner parts of gas turbine, and the drilling effect can realize three-dimensional direction, and the number can reach thousands. Materials that can be perforated include stainless steel, nickel chromium iron alloy and Hastelloy based alloy. Laser drilling technology is not affected by the mechanical properties of materials, and it is easy to realize automation.

With the development of laser drilling technology, the laser cutting machine has realized automatic operation. The application in the sheet metal industry has changed the processing method of traditional sheet metal technology, realized unmanned operation, greatly improved the production efficiency, realized the full-automatic operation in the whole process, driven the development of sheet metal economy, improved a level in the drilling effect, and the processing effect is remarkable.

Sheet metal industry as a basic processing industry It is widely used in many fields such as automobile, electronics and electrical appliances, engineering machinery and so on The position and weight in the market are becoming more and more important. Advanced laser cutting technology has attracted much attention in the sheet metal industry because of its outstanding characteristics and advantages.

According to your drawings (size, material, thickness, processing content, required technology, etc.)

Material: carbon steel, SPCC, SGCC, stainless steel, aluminum, brass, copper, etc

Processing: Laser cutting, precision stamping, bending, CNC punching, grinding, riveting, drilling, welding, and so on

Surface treatment: drawing, polishing, anodizing, powder coating, electroplating, screen printing, sandblasting, etc

Tolerance: ±0.1mm, 100%QC before delivery, can provide quality control table

Size: Accept custom size.

Colors: white, blank, silver, red, gray, Pantone, RAL, etc

Drawing format: DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI, PDF, JPG, draft.

Price terms: EXW, FOB, CIF, DDP, etc

Payment term: Sample: 100% payment before production

Mass production :(50% in advance as deposit, balance before delivery)

Certificate: ISO9001:2015 / SGS

Q1: Are you a factory or a trading company?

A: We are a factory, so we can offer you competitive prices.

Q2: What kind of services do you offer?

A: OEM sheet metal processing, CNC processing, stamping tool manufacturing, etc.

Q3: What information is required for a quotation?

A: In order to quote for you earlier, please provide us with the following information at the time of inquiry.

1. Detailed drawings (STEP,CAD,SOLID Works,DXF,PDF)

2. Material requirements (SUS,SPCC,AL,SECC,SGCC)

3.Surface treatment(powder coating,planting,sand blasting,polishing,oxidization,brushing,etc)

4. Quantity (per order/month/year)

5. Any special requirements or requirements, such as packaging, delivery, labeling, etc.

Q4: What if there are no drawings?

A: Please send your sample to our factory, then we can copy or provide you with a better solution, please send us pictures or sketches with dimensions (thickness, length, height, width), if the order is placed, CAD or 3D files will be made for you.

We have many years of experience in sheet metal, CNC processing production, has an advanced sheet metal processing production line, equipped with laser cutting, CNC shear, CNC punching, CNC bending, automatic riveting, automatic welding, automatic spraying, tooling, polishing, screen printing, assembly and another large workshop, has all kinds of advanced testing equipment, perfect testing process.

Product Categories : Sheet Metal Fabrication > Sheet Metal Stamping